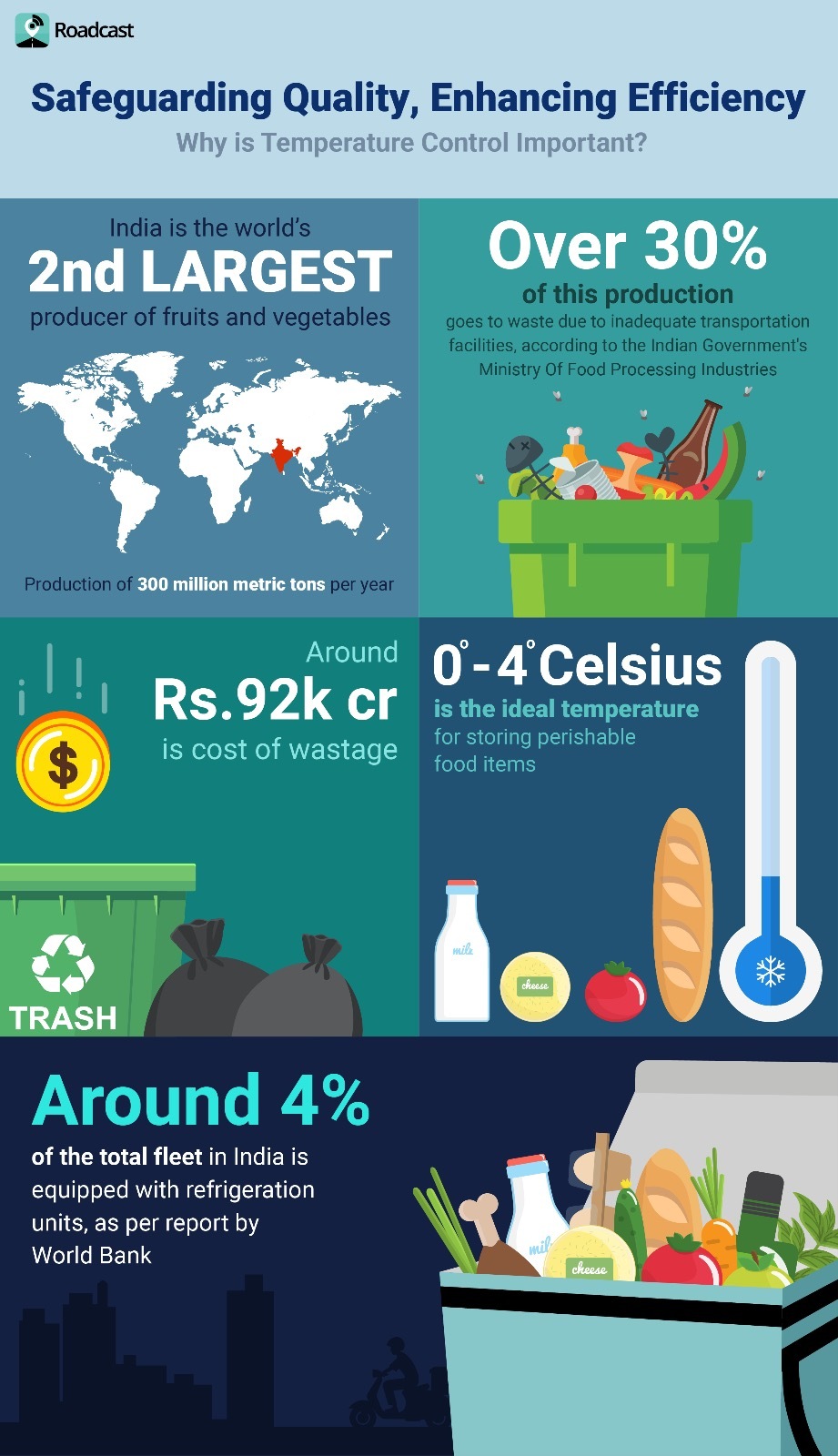

Food waste poses a challenge globally as a staggering amount of food produced for human consumption ends up being wasted. India grapples with a significant food wastage issue, resulting in an alarming economic loss of approximately 92,000 crore annually. However, amidst this challenge, technology is emerging as a pivotal tool in addressing the issue. Innovative solutions driven by technology are now actively reducing perishable loss and revolutionising the methods employed in food handling and distribution. Fleet and delivery management which includes cold chain technology i.e. refrigeration and temperature-controlled logistics, plays a crucial role in preventing spoilage and extending the shelf life of perishable food items. With the advent of IoT (Internet of Things), sensors and monitoring devices can now be installed in transportation vehicles to ensure that the optimal temperature and humidity conditions are maintained throughout the supply chain.

Smart Inventory Management

Traditional methods often lead to overstocking or inadequate monitoring of perishable goods, resulting in substantial waste. By implementing automation in diverse operations, enterprises can effectively reduce the consumption of time and resources typically associated with manual inventory tracking and management. By leveraging these advanced systems, businesses can accurately forecast demand, streamline supply chains, and prevent excess inventory. Moreover, this data can be used as valuable insights into consumer behaviour, market trends, and seasonality patterns. This allows one to make informed decisions about inventory stocking levels, pricing strategies, and promotional activities. By understanding customer preferences and purchasing patterns, businesses can optimise their inventory to meet demand while reducing the risk of overstocking or stockouts.

Specialised vehicles equipped with temperature-controlled systems, ensure that products are transported under the required conditions to minimise delays. Temperature sensors play a critical role in maintaining the integrity of the cold chain. They ensure that products are stored and transported at the correct temperature, preventing temperature fluctuations that can accelerate spoilage. Different products have specific temperature requirements, and deviations can affect their freshness and quality. By maintaining the ideal temperature, sensors help preserve the nutritional value, taste, and appearance of perishable goods reducing the likelihood of waste. Sensors embedded in storage facilities monitor temperature, humidity, and expiration dates, sending alerts to ensure timely consumption or removal of products nearing spoilage.

Real-time Tracking & Route Optimization

With real-time tracking capabilities, businesses can monitor inventory levels, shipment status, and delivery times. This visibility allows for better coordination with suppliers, distributors, and retailers, resulting in reduced lead times, less food spoilage and improved order fulfilment. It helps businesses identify potential bottlenecks or issues in the supply chain. By analysing data on shipment status and delivery times, businesses can pinpoint areas that require improvement and take proactive measures to address them. For example, if delays are consistently occurring in a specific transportation route, businesses can explore alternative options or work closely with logistics partners to find solutions. In the context of perishable goods, real-time tracking plays a crucial role in minimising food spoilage and waste. By monitoring temperature, humidity, and other environmental conditions in real-time, businesses can ensure that perishable items are stored and transported under optimal conditions.

Another effective way is to optimise transportation routes and schedules to minimise transit time and reduce the exposure of perishable goods to unfavourable conditions. One way is through route planning algorithms that take into account factors such as distance, traffic conditions, and delivery priorities. These algorithms consider various constraints and objectives, such as minimising travel distance, avoiding congested areas, and maximising on-time deliveries. Businesses can leverage real-time data, such as order volumes, delivery locations, and capacity constraints, to create optimised schedules for pickups, deliveries, and transportation vehicles. By strategically scheduling transportation activities, businesses can reduce idle time, maximise vehicle utilisation, and minimise the time that perishable goods spend waiting for transportation and optimal tech.

Towards a Sustainable Food System

Undoubtedly, technology driven fleet and delivery management enables seamless coordination, enhances transparency, and fosters a sense of community engagement in combating food waste. One significant aspect is the bridging of the gap between donation groups, businesses, and charities. Apps and online platforms have emerged as powerful tools that allow restaurants, grocery stores, and individuals to list their surplus food. Charitable organisations and food banks can then access these listings and claim the surplus food, ensuring it is redirected to those in need. This streamlined process eliminates barriers and facilitates efficient redistribution, preventing food from going to waste and instead reaching individuals who can benefit from it.

The utilisation of technology also addresses the environmental impact of food disposal. By preventing waste through surplus food redistribution, the strain on landfill capacities is reduced, minimising the environmental footprint associated with food waste disposal. Technology empowers stakeholders to work collectively towards reducing waste, alleviating food insecurity, and mitigating the environmental impact of food disposal. Continued innovation and adoption of technology in this realm will play a crucial role in achieving a more sustainable and equitable future for our food systems.