Why Yard Management is Crucial for Supply Chain Efficiency

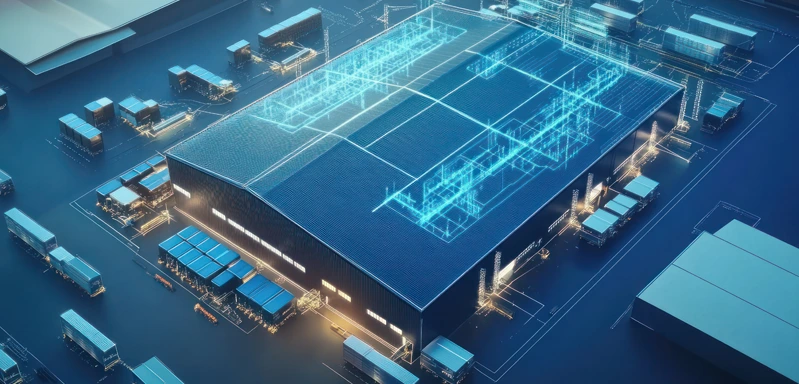

An optimized yard is the link between transportation and warehouse operations. Poor yard visibility leads to delayed shipments, idle trucks, and congestion—ultimately slowing down the entire supply chain. On the other hand, effective yard management improves overall performance by ensuring vehicles, trailers, and inventory are where they should be, when they should be.

Real-time tracking and visibility are at the heart of this transformation. Knowing the exact location and status of every vehicle, shipment and piece of equipment within your yard at any given moment, is crucial. This level of transparency allows for proactive decision-making ultimately accelerating the movement of goods from origin to destination.

Top Innovations in Yard Management for 2025

2025 marks a turning point in how technology transforms yard operations. Newer innovations are streamlining processes and reducing human error.

- AI-driven yard management systems leverage machine learning algorithms to predict traffic flows, optimize parking assignments, and even suggest the most efficient routes.

- IoT-enabled tracking is another game-changer. Small, inexpensive sensors transmit real-time location data, temperature, and other vital metrics. They capture yard data which can be accessed from a central platform for better visibility and efficient yard management.

- Automated gate management systems are streamlining entry and exit processes with IoT-powered Dockyard & Parking Management system that automates vehicle and cargo tracking, boosts security with AI-based license plate recognition, and provides real-time updates on driver info, parking, and vehicle status

For instance, one major e-commerce fulfillment company has implemented an AI-powered system that reduced average trailer dwell time by 20% and improved gate throughput by 30%, resulting in significant cost savings and faster delivery times. Another global manufacturer utilizes IoT sensors on all its trailers, enabling precise tracking and optimized staging, leading to a 15% reduction in detention fees.

Best Practices for Yard Management Optimization

Over and above adopting cutting-edge technology, implementing robust best practices is the key to successful yard management .

- Use Yard Management Software (YMS): A robust YMS helps track all yard assets—trailers, vehicles, containers—in real time. It also integrates with warehouse and transportation systems for seamless coordination.

- Real-time tracking constantly updates you on asset locations and status, giving you the flexibility to adjust operational plans as needed. Meanwhile, automated scheduling alleviates congestion and ensures a smooth flow of vehicles.

- Leverage Data Analytics: Data analytics and reporting tools are enablers for improving yard operations. Insightful data generated on dwell times, gate throughput, driver performance and equipment utilization, allow managers to identify bottlenecks, pinpoint inefficiencies, and make data-driven decisions.

These practices not only enhance efficiency but also provide long-term operational insights for scalability and growth.

How Yard Management Improves Operational Efficiency

By automating routine tasks Companies can:

- Lower fuel and labor costs through reduced wait times

- Decrease detention and demurrage charges with timely check-ins and departures

- Increase labor productivity by allocating resources appropriately

- Boost security and compliance IoT-powered Dockyard & Parking system boosts security with AI-based license plate recognition, and provides real-time updates on driver info, parking, and vehicle status.

The role of real-time data in reducing delays and increasing throughput is paramount. When yard managers have immediate access to information about incoming and outgoing shipments, available dock doors, and trailer locations, they can make agile decisions to prevent bottlenecks and keep goods flowing.

Future Trends to Watch in Yard Management Beyond 2025

- AI & Machine Learning: Future systems will optimize schedules based on real-time traffic or inventory levels. It will forecast delays, suggest preventive actions, and Machine learning will enable systems to learn and adapt to increasingly complex scenarios, handling unforeseen disruptions with greater autonomy.

- Autonomous vehicles could play a huge role in the future. Internal yard movements and inventory checks could be managed by self-driving trucks and aerial drones. Tasks like trailer spotting and inter-yard shuttling could further reduce manual labor and enhance safety.

- Fleet and Yard Integration: As fleet management technology advances, its integration with yard systems will offer complete visibility from point A to B, allowing organizations to optimize end-to-end logistics like never before.

Companies that stay ahead of these trends will enjoy a competitive advantage in cost, speed, and reliability.

Conclusion

In order to stay competitive businesses will have to adopt advanced yard management systems. The benefits are clear: reduced costs, increased efficiency, improved visibility, and ultimately, a more agile and responsive supply chain.

Whether you operate a single facility or manage a nationwide distribution network, innovations in yard management systems for 2025 offer the tools needed to streamline operations, cut costs, and improve supply chain performance.